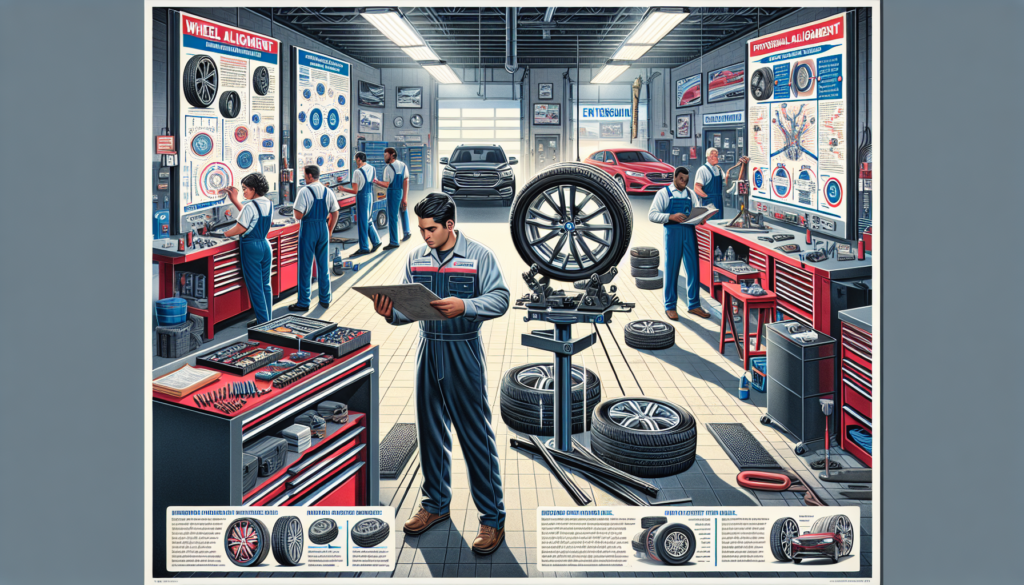

Have you ever wondered what exactly goes on during a professional wheel alignment? Whether it’s your first time bringing your car in or you’re just curious about the process, understanding what happens during a wheel alignment can help you maintain the health and performance of your vehicle. From measuring tire angles to adjusting suspension components, a professional wheel alignment ensures that your wheels are properly aligned and your car drives smoothly and efficiently. So, let’s take a closer look at the fascinating world of wheel alignments and discover all that goes on behind the scenes to keep your car on the right track.

What Happens During A Professional Wheel Alignment?

If you’ve ever wondered what happens during a professional wheel alignment, you’re in the right place! Having a proper wheel alignment is crucial for maintaining the safety and performance of your vehicle. It ensures that all four wheels are angled correctly and parallel to each other, allowing for optimal tire contact with the road surface. A professional wheel alignment involves several key steps to ensure that your vehicle’s alignment is set to the manufacturer’s specifications. Let’s dive into each step to get a better understanding.

Inspection of Tires

The first step in a professional wheel alignment is the inspection of tires. The technician will carefully examine each tire for any signs of wear, damage, or uneven tread wear. This inspection is essential as it helps identify any underlying issues that may affect the alignment of the wheels.

Measurement of Wheel Alignment Angles

Once the tires have been inspected, the technician will use specialized equipment to measure the wheel alignment angles. This includes measuring the camber, toe, and caster angles. These measurements provide a baseline for determining the correct alignment settings for your vehicle.

Adjustment of Camber Angle

Camber angle refers to the inward or outward tilt of the wheels when viewed from the front of the vehicle. The technician will adjust the camber angle to the manufacturer’s specifications. Correct camber alignment ensures that the tires are properly centered on the road, promoting even tire wear and better vehicle stability.

Adjustment of Toe Angle

Toe angle refers to the angle at which the tires point inward or outward when viewed from above. The technician will adjust the toe angle to the manufacturer’s specifications. Proper toe alignment helps ensure that the tires are parallel to each other, reducing tire wear and improving fuel efficiency.

Adjustment of Caster Angle

Caster angle refers to the forward or backward tilt of the steering axis when viewed from the side of the vehicle. The technician will adjust the caster angle to the manufacturer’s specifications. Correct caster alignment helps in maintaining straight-line stability and enhances the vehicle’s steering response.

Inspection and Adjustment of Thrust Angle

The thrust angle is the angle at which the rear wheels deviate from the vehicle’s centerline. If a vehicle has a rear-wheel drive, the technician will inspect and adjust the thrust angle as necessary. Proper thrust alignment ensures that all four wheels are properly aligned, enhancing overall vehicle handling and stability.

Inspection and Adjustment of Ride Height

During a professional wheel alignment, the technician will also inspect and adjust the ride height. Ride height refers to the distance between the ground and specific points on the vehicle’s chassis. Proper ride height adjustment ensures that the vehicle’s weight is distributed evenly, promoting optimal tire contact with the road surface.

Inspection and Adjustment of Steering Axis Inclination

Steering axis inclination refers to the angle created by a line drawn through the upper and lower ball joints of the steering system and a vertical line. The technician will inspect and adjust the steering axis inclination if necessary. Proper steering axis inclination improves steering control and stability while reducing tire wear.

Inspection and Adjustment of SAI/KPI Angle

SAI stands for Steering Axis Inclination, and KPI refers to Kingpin Inclination. These angles determine the relationship between the steering knuckle and the vertical axis. The technician will inspect and adjust the SAI/KPI angle to the manufacturer’s specifications. Correct SAI/KPI alignment ensures proper steering response and stability.

Testing and Road-Testing

Once all the adjustments have been made, the technician will conduct a series of tests to ensure the wheel alignment is correct. This includes checking the steering wheel’s position, verifying the vehicle’s straight-line stability, and evaluating its handling characteristics. If necessary, a road test may also be performed to further assess the alignment’s effectiveness under real-world driving conditions.

In conclusion, a professional wheel alignment involves a thorough inspection of tires, followed by precise measurements and adjustments of various wheel alignment angles. This process ensures that your vehicle’s wheels are aligned according to the manufacturer’s specifications, promoting optimal tire wear, fuel efficiency, and overall vehicle performance. By entrusting your vehicle to a professional technician, you can rest assured that your wheel alignment is in capable hands, keeping you safe and confident on the road. So, the next time you experience any signs of misalignment or plan on replacing tires, don’t forget the importance of a professional wheel alignment.