If you’ve ever wondered how to make sense of wheel alignment measurements, you’ve come to the right place. Understanding these measurements can help you improve the performance and longevity of your vehicle’s tires, while also ensuring a safer and more comfortable ride. From camber to toe to caster, this article will provide you with a clear and friendly breakdown of how to interpret these measurements and what they mean for your vehicle. So, let’s jump right in and demystify the world of wheel alignment!

Understanding Wheel Alignment

Definition of Wheel Alignment

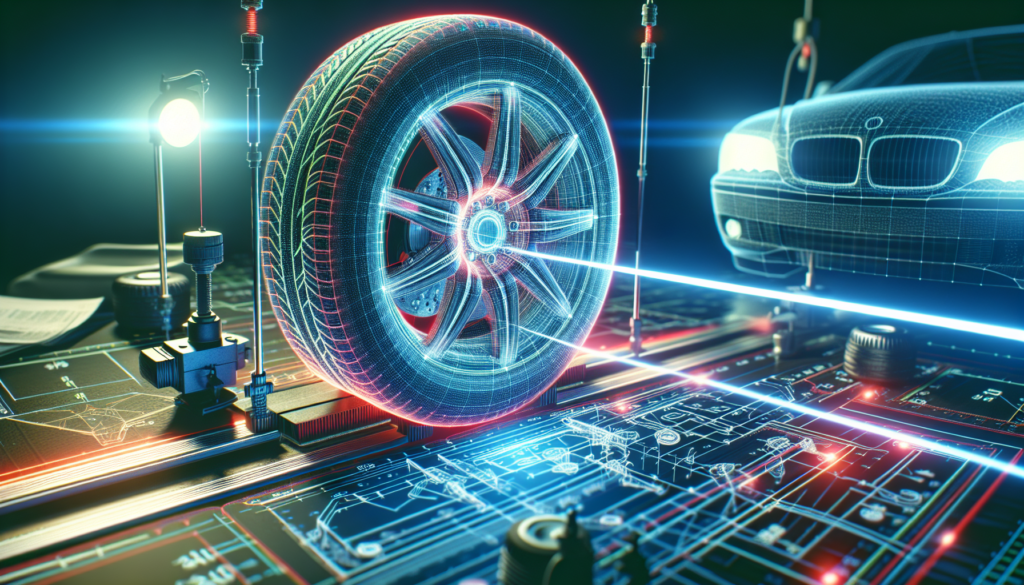

Wheel alignment refers to the adjustment of the angles of the wheels so that they are perpendicular to the ground and parallel to each other. It is an essential aspect of vehicle maintenance that ensures optimal performance and safety on the road. Proper alignment helps to maintain even tire wear, maximizes fuel efficiency, improves handling and stability, and prolongs the life of various suspension components.

Importance of Wheel Alignment

Having your wheels properly aligned is crucial for several reasons. First and foremost, it enhances safety by ensuring that your vehicle handles properly, especially during emergency maneuvers or adverse road conditions. Correct alignment also promotes consistent and even tire wear, which not only extends the lifespan of your tires but also improves fuel efficiency. Furthermore, proper wheel alignment helps to prevent premature wearing of suspension components, such as ball joints and tie rod ends, saving you from costly repairs down the line.

Components of Wheel Alignment

Wheel alignment consists of several measurements and adjustments that ensure the wheels are in the correct position. These include camber, toe, caster, thrust angle, SAI (Steering Axis Inclination), and included angle. Each measurement plays a crucial role in the overall alignment of the vehicle and affects different aspects of the steering and handling characteristics.

Types of Wheel Alignment

Front-end Alignment

Front-end alignment, also known as two-wheel alignment, focuses on adjusting the front wheels’ angles. This type of alignment is common in vehicles with a solid rear axle, such as trucks and older sedans. Front-end alignment primarily involves adjusting the camber and toe settings of the front wheels to ensure proper alignment and even tire wear.

Four-wheel Alignment

Four-wheel alignment, as the name suggests, involves adjusting the angles of all four wheels. This type of alignment is common in modern vehicles with independent suspension on all wheels. Four-wheel alignment includes adjustments to the camber, toe, and caster angles on both the front and rear wheels, ensuring optimum alignment and overall vehicle stability.

Thrust Alignment

Thrust alignment focuses on correcting the thrust angle, which is the angle formed between the vehicle’s centerline and the rear axle. A misaligned thrust angle can cause the vehicle to pull to one side, leading to uneven tire wear and compromised handling. Thrust alignment ensures that the thrust angle is parallel to the vehicle’s centerline, promoting straight-line stability.

Wheel Alignment Measurements

Camber

Camber refers to the vertical tilt of the wheels when viewed from the front or rear of the vehicle. It is measured in degrees and can be either positive or negative. Positive camber means that the top of the wheel tilts outward, while negative camber indicates a tilt inward. Camber influences tire wear, traction, and cornering stability, and incorrect camber angles can lead to uneven tire wear and reduced handling performance.

Toe

Toe refers to the angle at which the tires point inward or outward when viewed from the top of the vehicle. Toe settings are crucial for the vehicle’s straight-line stability and tire wear. When the front of the tires point inward, it is called toe-in, while outward-pointing tires are known as toe-out. Incorrect toe settings can result in excessive tire wear, erratic steering, and poor handling.

Caster

Caster is the angle formed between the steering axis and a vertical line when viewed from the side of the vehicle. It determines the steering stability and self-centering ability of the wheels. Positive caster indicates the steering axis tilting toward the driver, while negative caster implies the opposite. Proper caster alignment promotes straight-line stability and enhances the vehicle’s ability to return to a centered position after turning.

Thrust Angle

Thrust angle refers to the direction in which the rear wheels are positioned in relation to the vehicle’s centerline. It is crucial for maintaining the vehicle’s straight-line stability and preventing it from pulling to one side. A misaligned thrust angle can result from various factors, such as improper wheel alignment, damaged suspension components, or a collision. Correcting the thrust angle ensures that the vehicle’s rear wheels are parallel to the front wheels, promoting stability and balanced tire wear.

SAI (Steering Axis Inclination)

SAI, or Steering Axis Inclination, is the angle formed between the steering axis and a line perpendicular to the ground when viewed from the front of the vehicle. SAI plays a crucial role in ensuring proper steering and turning characteristics. A higher SAI angle provides better self-centering and stability during cornering, while a lower SAI angle enhances steering response. Incorrect SAI angles can result in uneven tire wear, steering pull, and compromised handling.

Included Angle

The included angle refers to the sum of the camber and SAI angles. It provides additional information about the wheel alignment. Combining these two angles allows for a comprehensive assessment of the steering and suspension system and helps determine if any adjustments are needed to achieve optimal alignment.

Interpreting Camber Measurements

Understanding Camber

Camber is one of the fundamental wheel alignment measurements that significantly impacts tire wear and handling. It ensures that the tire’s contact patch remains flat on the road surface during turns. Proper camber alignment helps distribute the vehicle’s weight evenly across the tire tread, maximizing grip and preventing premature wear on the inside or outside edges of the tire.

Positive Camber

Positive camber refers to the top of the wheel tilting outward when viewed from the front or rear of the vehicle. It is commonly seen in vehicles with solid rear axles and has a few specific applications, such as improving stability when carrying heavy loads. However, excessive positive camber can result in uneven tire wear on the outer edges, reduced cornering grip, and a tendency for the vehicle to wander or pull to one side.

Negative Camber

Negative camber, on the other hand, indicates the top of the wheel tilting inward. It is commonly used in performance vehicles or sports cars to improve cornering grip and stability. Negative camber allows for more tire contact during aggressive turns, reducing the likelihood of the tire rolling onto its sidewall. However, excessive negative camber can lead to excessive wear on the inner edges of the tires, reduced straight-line stability, and increased road noise.

Effects of Incorrect Camber

Incorrect camber can have various negative effects on your vehicle’s performance and safety. Excessive positive or negative camber can result in uneven tire wear, reduced traction, compromised handling, and increased braking distances. It can also put additional stress on suspension components, leading to premature wear and potential failure. Regular wheel alignments are essential to ensure proper camber alignment and maintain the longevity and performance of your tires and suspension system.

Interpreting Toe Measurements

Understanding Toe

Toe is another crucial wheel alignment measurement that affects both tire wear and straight-line stability. It refers to the angle at which the tires point inward or outward when viewed from above the vehicle. Proper toe alignment ensures that the tires roll parallel to each other, minimizing tire scrubbing and maximizing tire contact with the road.

Toe-In vs. Toe-Out

Toe alignment can be classified as either toe-in or toe-out. Toe-in means that the front edges of the tires are closer together than the rear edges, giving the appearance of the tires pointing inward. This setup promotes straight-line stability but can lead to increased tire wear on the outer edges. In contrast, toe-out indicates that the front edges of the tires are farther apart than the rear edges, resulting in a slight outward-pointing appearance. Toe-out enhances cornering responsiveness but can cause excessive wear on the inner edges of the tires.

Effects of Incorrect Toe

Incorrect toe alignment can have detrimental effects on tire wear and handling. Excessive toe-in or toe-out can cause rapid and uneven tire wear, reducing the tire’s lifespan and compromising overall performance. It can also result in increased rolling resistance, leading to decreased fuel efficiency. Additionally, incorrect toe alignment can cause the vehicle to pull to one side, requiring constant steering correction and making driving unsafe. Regular wheel alignments are essential to maintain proper toe alignment and ensure optimal tire performance and vehicle handling.

Interpreting Caster Measurements

Understanding Caster

Caster is a critical wheel alignment measurement that affects steering stability and self-centering ability. It refers to the angle formed between the vehicle’s steering axis and a vertical line when viewed from the side. Proper caster alignment is crucial for straight-line stability, steering response, and overall driving comfort.

Positive Caster

Positive caster indicates that the steering axis tilts toward the driver when viewed from the side of the vehicle. It helps enhance straight-line stability by ensuring that the wheels naturally want to return to a centered position after turning. Vehicles with positive caster generally exhibit better high-speed stability and reduced sensitivity to crosswinds.

Negative Caster

In contrast, negative caster implies that the steering axis tilts away from the driver. While negative caster can improve low-speed maneuverability, it typically results in reduced straight-line stability and less responsive steering. Negative caster is generally not utilized in most vehicles and may indicate an issue with the wheel alignment or suspension system.

Effects of Incorrect Caster

Incorrect caster alignment can have a significant impact on your vehicle’s steering and handling characteristics. Excessive positive or negative caster can lead to steering pull, uneven tire wear, and increased effort required to steer the vehicle. It can also result in poor self-centering ability, making it challenging to maintain a straight course. Regular wheel alignments are crucial to address any incorrect caster angles and ensure optimum steering performance and driver safety.

Interpreting Thrust Angle Measurements

Understanding Thrust Angle

Thrust angle refers to the direction in which the rear wheels are positioned in relation to the vehicle’s centerline. It is crucial for maintaining straight-line stability and preventing the vehicle from pulling to one side while driving. A properly aligned thrust angle ensures that the rear wheels are parallel to the front wheels, resulting in balanced tire wear and improved handling.

Effects of Incorrect Thrust Angle

An incorrect thrust angle can lead to several adverse effects on your vehicle’s performance and safety. If the rear wheels are misaligned and not parallel to the front wheels, the vehicle may exhibit a tendency to veer to one side continuously. This can make driving unsafe and require constant steering correction to maintain a straight course. Additionally, an incorrect thrust angle can cause uneven tire wear, premature suspension component failure, and compromised handling. Regular wheel alignments, especially thrust alignments when necessary, are vital to correct any misalignments and ensure optimal vehicle stability.

Interpreting SAI Measurements

Understanding SAI

SAI, or Steering Axis Inclination, is the angle formed between the steering axis and a line perpendicular to the ground when viewed from the front of the vehicle. It plays a crucial role in steering stability, promoting self-centering ability, and maintaining proper tire contact with the road during turns.

Effects of Incorrect SAI

Incorrect SAI angles can have negative consequences on your vehicle’s steering and handling characteristics. Excessive or insufficient SAI can result in uneven tire wear, drifting or pulling to one side, and increased steering effort. It can also affect the vehicle’s ability to maintain control during cornering, leading to reduced overall stability. Regular wheel alignments are necessary to correct any SAI misalignments and ensure optimal steering performance and tire longevity.

Interpreting Included Angle Measurements

Understanding Included Angle

The included angle is the sum of the camber and SAI angles. It provides valuable information about the overall wheel alignment and allows for a more comprehensive assessment of the vehicle’s steering and suspension system.

Effects of Incorrect Included Angle

An incorrect included angle can significantly impact your vehicle’s alignment and performance. Excessive or insufficient included angles can lead to uneven tire wear, compromised handling, and reduced overall stability. A comprehensive wheel alignment, considering both camber and SAI measurements, is crucial to correct any included angle misalignments and ensure optimal steering response, tire wear, and safety.

Using Alignment Specifications

Manufacturer’s Recommended Specifications

Every vehicle has specific wheel alignment specifications provided by the manufacturer. These specifications outline the optimal range within which the various alignment angles should be adjusted to ensure the vehicle performs as intended. It is essential to consult the vehicle’s owner’s manual or a trusted mechanic to determine the manufacturer’s recommended alignment specifications for your specific make and model.

Acceptable Ranges

While the manufacturer’s recommended specifications provide a guideline, there are acceptable ranges within which the alignment angles can deviate. These ranges are based on the vehicle’s design, suspension characteristics, and intended use. Aligning the wheels within the acceptable ranges allows for some flexibility while still maintaining proper alignment and performance.

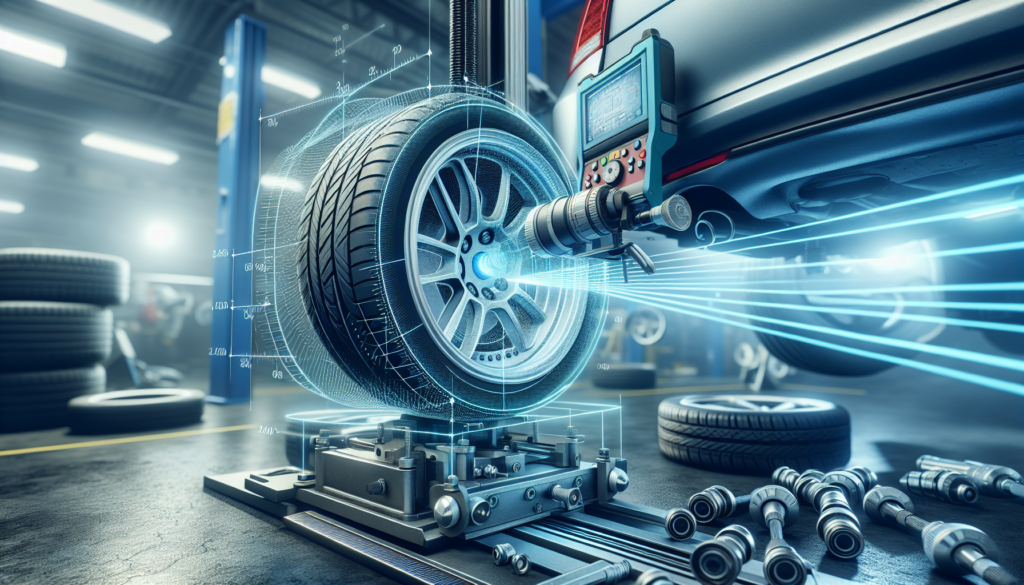

Adjusting Wheel Alignment

Wheel alignment adjustments should always be performed by a qualified technician using specialized equipment. Depending on the type of alignment required, the technician will adjust the relevant alignment angles to bring them within the manufacturer’s recommended specifications. This process may involve adjusting suspension components, such as tie rods, control arms, or eccentric bolts, to achieve the desired alignment angles. Once the adjustments are made, the technician will perform a final check to ensure that all the alignment angles are within the acceptable ranges and that the vehicle handles and performs optimally.

In conclusion, understanding and interpreting wheel alignment measurements is vital for optimal vehicle performance, safety, and tire longevity. Camber, toe, caster, thrust angle, SAI, and included angle all play crucial roles in the overall alignment of the wheels. Regular wheel alignments, performed by qualified technicians using specialized equipment, help correct any misalignments and ensure that the wheels are perpendicular to the ground and parallel to each other. By maintaining proper wheel alignment, you can enjoy improved handling, stability, tire wear, and fuel efficiency, while also prolonging the life of your suspension components.